Non Destructive Testing

Nondestructive Testing (NDT)

A type of quality control inspection that does not harm the part being tested. NDT Inspectors use sophisticated technology to look through steel and concrete to identify and diagnose flaws without disrupting the integrity of the structure. An example of Nondestructive Testing would be performing x-ray on a pipe weld to look for cracks that might cause a leak.

Dye penetrant inspection (DPI), Liquid penetrant inspection (LPI)

A widely applied and low-cost inspection method used to locate surface-breaking defects in all non-porous materials (metals, plastics, or ceramics). The penetrant may be applied to all non-ferrous materials and ferrous materials. LPI is used to detect casting, forging and welding surface defects such as hairline cracks, surface porosity, leaks in new products, and fatigue cracks on in-service components.

Magnetic particle Inspection (MPI)

A non-destructive testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization.

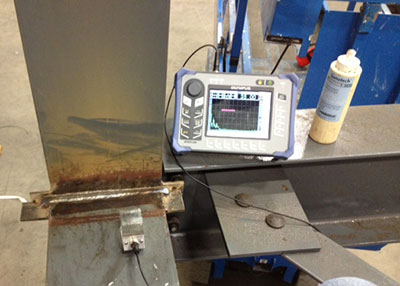

Ultrasonic testing (UT)

A family of non-destructive testing techniques based in the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz, and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion.

Quality Assurance/Control

- Quality Assurance:WW NDT Services Inspectors combined over 4 decades of experience in the Non Destructive Testing and inspection field gives our customers the assurance & certainty needed for their product/project.

- Quality Control:WW NDT Services Inspector know how to create and then apply the correct procedures to the needed tasks. These procedures will provide guidance so our customers know they will be creating a safe and quality product every time, every weld.

WW NDT Services inspector know the needed tests and observation techniques used to fulfill requirements for a quality product every time.

AWS/CWI Inspection

The purpose of welding inspection is to determine if a weldment meets the acceptance criteria of a specific code, standard, or other document. The welding inspector must be thoroughly familiar with welding processes, welding procedures, welder qualifications, materials, the limitation of weld testing, be able to read drawings, prepare and keep records, prepare and make reports, and make responsible judgments. For welding inspectors to be effective, the activities performed should be consistent with the requirements, and technical and ethical principles.